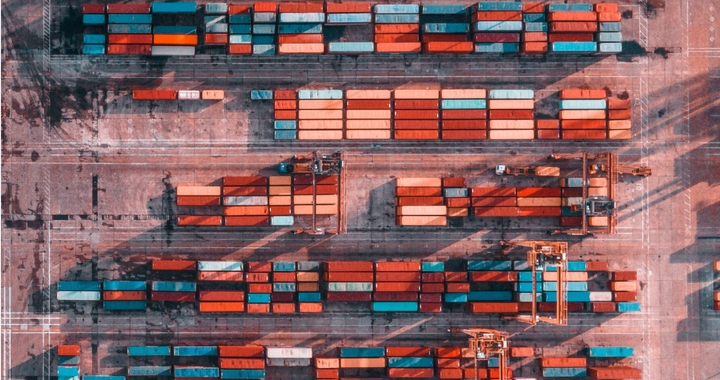

Peak Season Price Spike

The ocean freight industry is an integral part of global commerce. When you're shipping goods, ocean freight can be the most cost-effective way to get your products where they need to go. However, ocean freight rates are not static; they fluctuate with demand and supply. This article looks at peak season price spikes in ocean cargo rates and how it affects both shippers and consignees.

What is peak season for shipping?

When demand for ocean shipping is high, carriers release special rates to meet the need. These usually last no more than a few weeks or months before prices return to normal. Peak periods create major changes in space availability and demurrage charges (a fee incurred when cargo arrives at its destination after time has expired).

The biggest impact on shippers comes from the ocean freight peak season surcharge that is often applied by the carriers during these times of increased volume/demand due to an increase in fuel costs.

Some examples include:

- Security Surcharge

- Bunker Adjustment Factor (BAF)

- Volatile Organic Compounds Surcharge (VOC)

Security Surcharge

When you are shipping a package that is worth over $500, the company might ask for an additional fee. This security surcharge in shipping makes sure your package will be shipped safely and securely.

The amount of this surcharge depends on how expensive your item is. For example, if your product cost around $700 then you have to pay about $25 extra as security surcharges in shipping fees.

Bunker Adjustment Factor (BAF)

BAF is an extra charge added to the base freight rate. It reflects costs for fuel, port charges, and other additional expenses that are associated with the transportation of goods by sea. BAF can vary from one company to another depending on how much they need to cover their overheads or make a profit out of it.

A standard rule when shipping cargo via containers is purchasing services at spot rates rather than entering into long-term contracts because bunker prices change daily. This makes it difficult to calculate if you have entered into optimal contract terms or not as price fluctuations could be significant and unforeseen changes may take place in market conditions too after the deal has been made which might affect your business’s budgeting efforts adversely afterward.

Volatile Organic Compounds Surcharge (VOC)

The VOC surcharge is a state-imposed fee on the purchase of motor fuels in California. The fees help fund programs to reduce emissions from smog and toxic air pollutants.

When does peak season start?

The peak season usually starts in the months of January, February, and March.

When is peak season in global shipping?

Peak season in global shipping lasts from January to March every year. This is when shippers are trying to move inventory before their fiscal year closes.

Why is there a price spike during peak season?

The main reasons for this peak season trend can be attributed to the following:

- Weather delays in Europe and Asia (e.g., typhoons, monsoons) that lead to congestion at major ports like Hong Kong, Singapore, Rotterdam, Shanghai & Ningbo

- Manufacturers use January to February as a time of production cutbacks or shutdowns which affects supply chains with reduced volumes

- The Chinese New Year holiday period during late January through early February where manufacturing plants close down for up to two weeks leading to very low rates due to lower demand

Shipping Container Cost During Peak Season

The shipping container price in peak season is usually about $2600. However, this can vary from one location to another and from destination to destination. In some parts of the world, containers are more expensive at certain times of year than others because there's less competition among shippers during those periods.

Shipping container costs between mid-October and early December will also be more expensive. The cost of a shipping container during the holiday rush may be as high as $3000. The holiday rush will have an increase in prices, which may include additional service charges like trucking, packing materials, etc.

The costs of other services that are often included in the price of a container can also vary depending on time and location. Costs for trucking, packing material, storage, gate fees at ports can all change from season to season as well.

What is the difference between GRI and peak season?

GRI is a booking made in one single month, whereas peak season rates are usually booked and effective for the highest booking volumes. The GRI rate has no impact on shippers while it's important to be aware of carrier surcharges that could affect your bottom line during the high volume months.

How does this affect my shipping?

The difference between what you would pay if you were to ship out at the GRI rate versus the peak season surcharge in ocean freight can add up quickly depending upon how much inventory you need to move.

Every business will have different needs when it comes down to which option works best for them.

How to prepare for peak season in global shipping

Prepare for peak season in global shipping with helpful tips and tricks. Save yourself some stress by following these simple guidelines:

1. Adequate Planning

The best way to prepare for peak season in global shipping is to make sure your eCommerce store has a plan well ahead of time. Ask yourself, what steps must be taken before the rush begins? Are there any processes that need to be streamlined or reworked over time? What can I do now that will set me up for success when it comes down to crunch time and things get hectic around here?

2. Manage Your Inventory

Another important step you can take to prepare for peak season is to manage inventory levels so that there are no shortages during the rush. This way, customer service isn't bogged down with misplaced items and other issues because everything will be in stock when it's needed most!

3. Keep Customers Informed

Make sure customers know where their order stands throughout the process too- regardless of whether they've placed an order or not. Whether it's through email marketing campaigns or social media updates, keep them informed about what's happening behind the scenes at all times.

4. Improve Your Customer Service

Having a dedicated customer service team is key to keeping customers satisfied during the busy holiday season. But having too many people on staff can be overwhelming and cause more problems than it solves, especially if there's miscommunication or lack of organization among employees. Make sure everyone knows what they need to do and when so that no business hours are wasted with unproductive tasks!

5. Train Your Staff

Even if you only have one employee working in your warehouse for peak season, he/she should know exactly where everything needs to go, how things work around here and all other necessary information so nothing slows down productivity while orders come flying in left and right. Ensure this by making training mandatory before any shift begins!

What can be done to avoid peak season overload?

There are a number of things that shippers can do to prepare for the cargo rate increases. Shipping goods early during off-peak times is one great option, but certain factors need to be taken into consideration such as production lead times or getting products from suppliers on time.

A lot depends on how fast you want your products delivered after they leave port - whether it's just days before the new fiscal year starts or several weeks ahead of schedule. Shippers also have options when it comes down to moving their freight - by air instead of ocean transport which incurs additional costs.